Implementation video

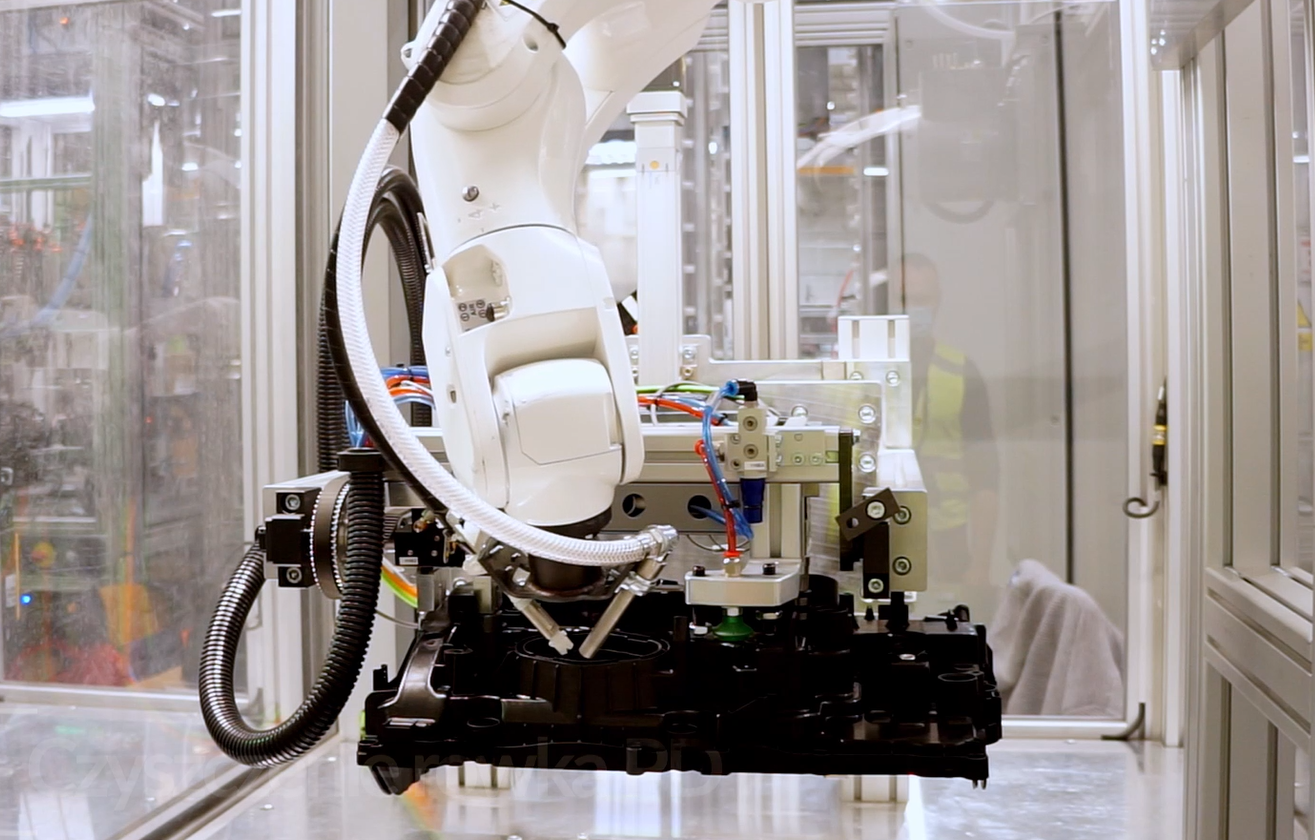

Bruss Polska, a company specializing in supplying components for the automotive industry, is executing a major project for one of the leading passenger car manufacturers. To achieve this, the company collaborates with Smart Automation integrators, launching a new production line at its factory utilizing KUKA KR AGILUS robots.

Bruss is one of the top suppliers of components for the automotive industry, with a client portfolio that includes brands such as Daimler, BMW, and Volkswagen. Founded in the 1950s, the company remains family-owned but operates internationally. Bruss has factories in six countries, including Poland, where Bruss Polska was established in 2004.

The company’s headquarters and production facility are located in Mrągowo, in the Warmian-Masurian Voivodeship.

Since 2019, one of the company’s largest projects has been underway at the Bruss Polska factory in Mrągowo. The project aims to produce valve covers for three-liter diesel engines installed in selected vehicles of a key Bruss client.

To implement the project, the Mrągowo facility needed to create a new assembly line that would maximize automation while minimizing the number of operators. Automotive industry quality requirements were also critical, making it essential to implement solutions that ensure high process repeatability while maintaining the desired throughput. Ultimately, the management of Bruss Polska chose us as a trusted partner — we have been collaborating for over 10 years.

As Krystian Szymański, Maintenance Engineer at Bruss Polska, emphasizes: “We have been executing projects with Smart Automation for years and know we can trust them — it just works. Additionally, we wanted the highest possible level of automation, which we achieved. On a large-scale line, only three operators are required.

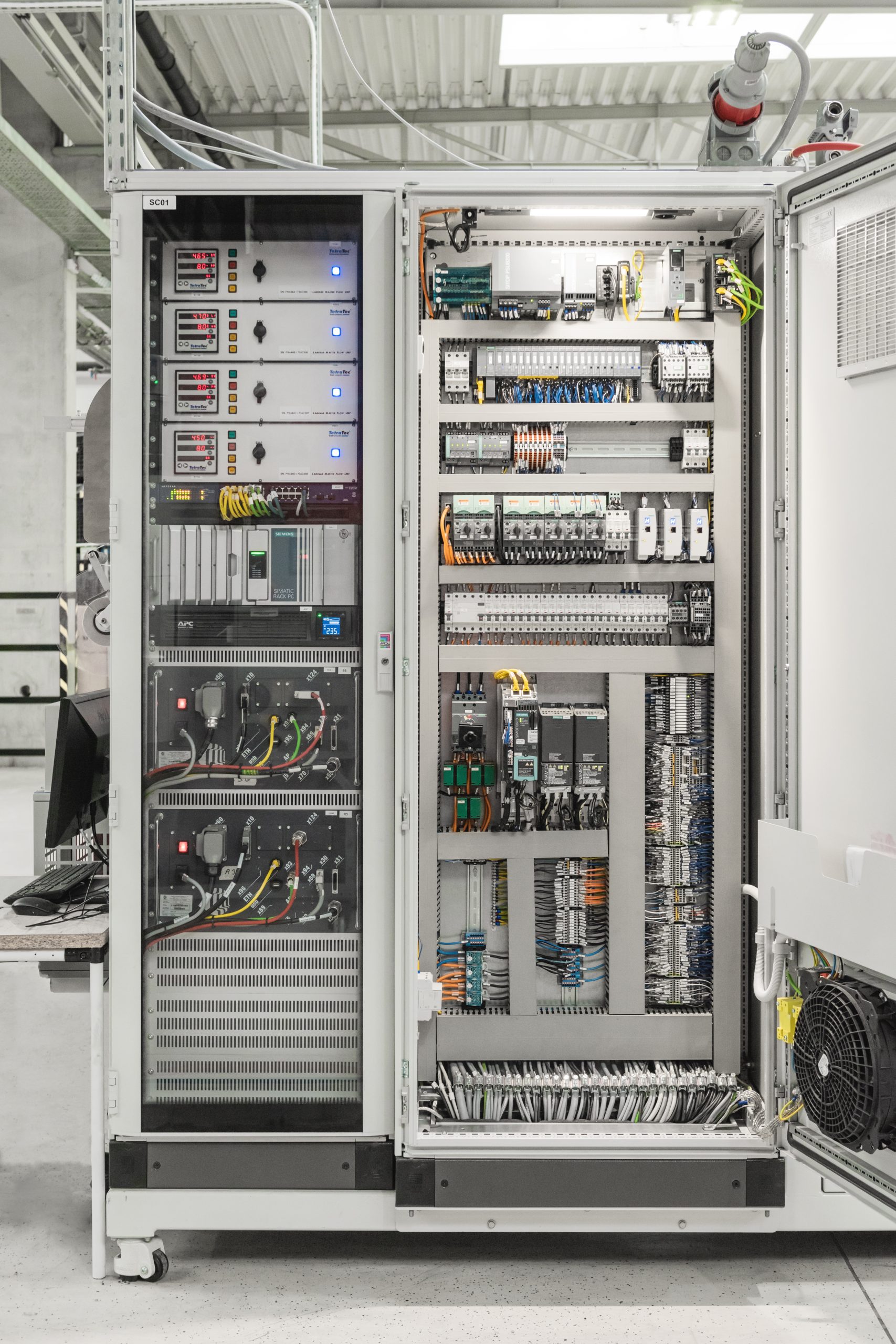

The production line created by Smart Automation consists of 16 interconnected modules. Two of these are KUKA KR Agilus robot stations, responsible for cleaning the areas under the valve cover seals and performing precise measurements, respectively.

Thanks to the use of robots — particularly the one responsible for measuring several different characteristics — we managed to reduce the number of operators needed to run the line from sixteen to three,” says Krystian Szymański, Maintenance Engineer at the Bruss Polska factory.

Arkadiusz Hirsch, a robot programmer at Smart Automation, provides a detailed overview of the valve cover assembly line launched in 2019:

,,The line consists of several stations, including the insert assembly station, pressure testing station, and stations with KUKA robots. The first KUKA robot station is equipped with a cleaning system that blows compressed air and removes particles from areas designated for seal installation to maintain the sterility of the valve covers.”

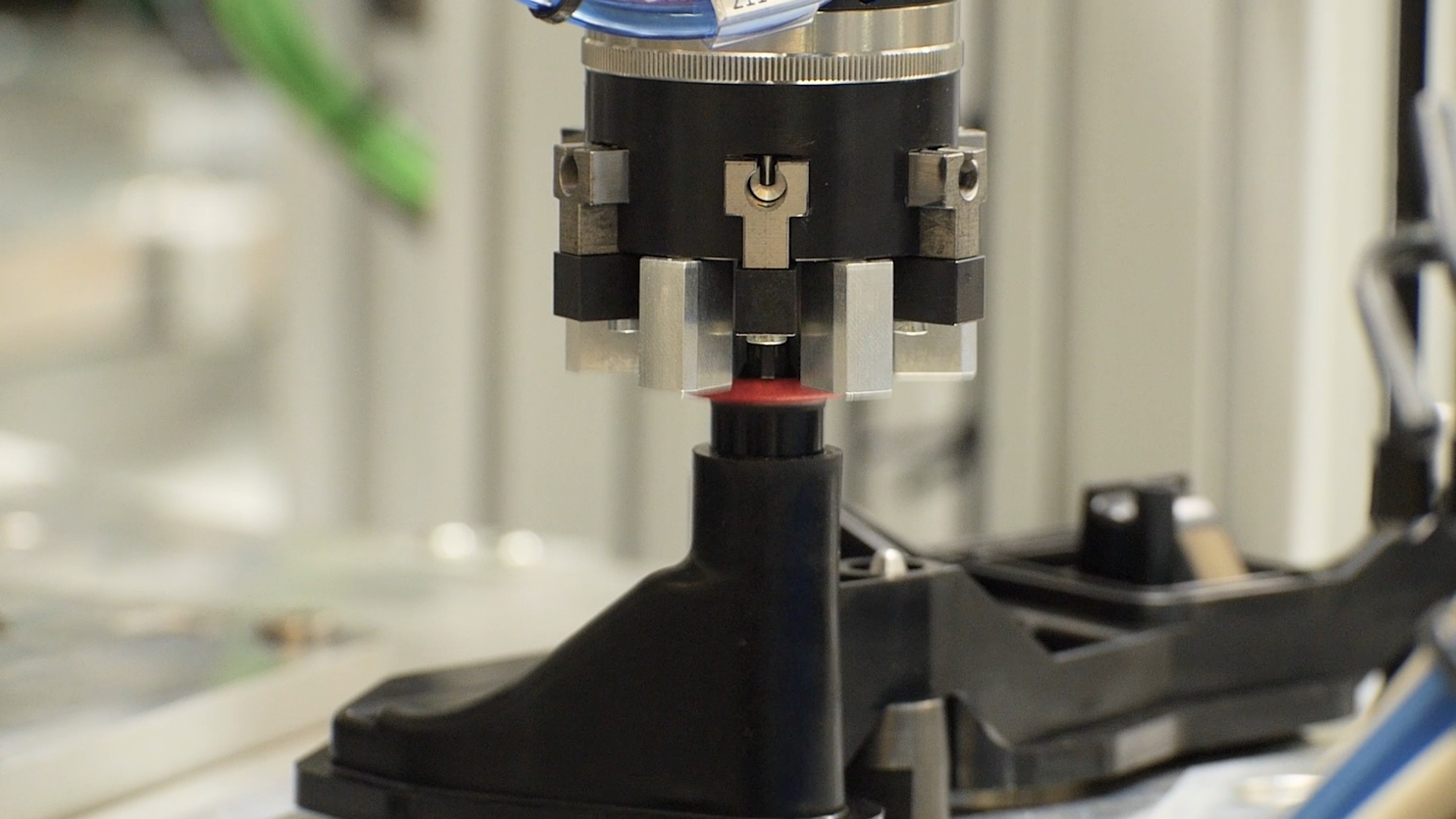

,,The second KUKA robot station was designed to measure the characteristic properties of the valve covers, such as hole ovality, diameter, and spatial position.

During measurements, the robot records data from the confocal sensor mounted on it, allowing multiple contactless measurements to be performed without the risk of damaging the part’s surface.”

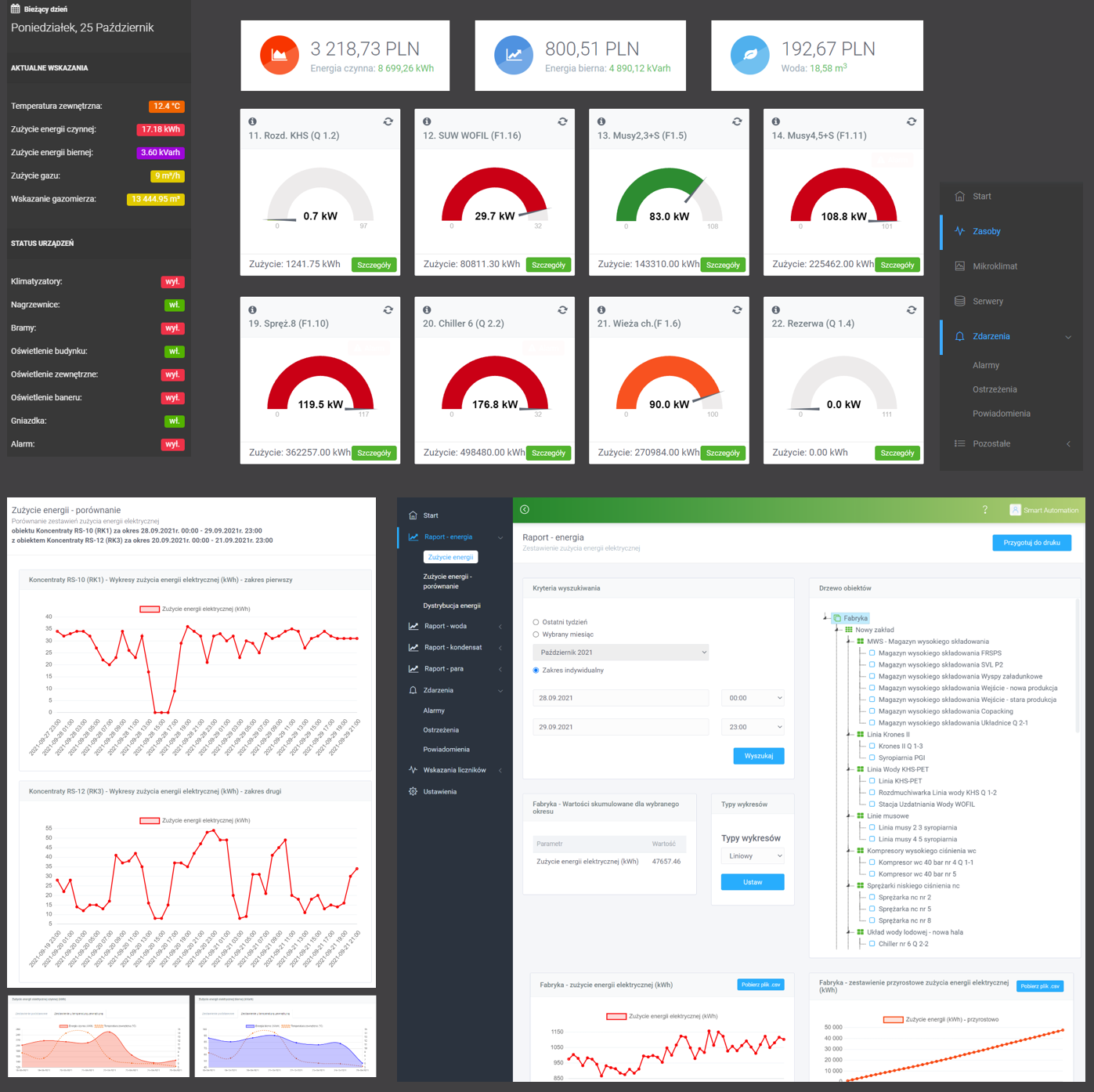

The data collected by the sensor is recorded and transmitted to a central server that manages the line. This allows the data to be analyzed via a web browser by logging into our specialized reporting system – the interviewee explains.

The use of the confocal sensor by the Smart Automation team was based on specific advantages. The most important for the application created for Bruss Polska are the sensor’s small size and its nanometer-level resolution, regardless of the type of surface being measured.

Łukasz Szczepkowski, Sales Engineer at KUKA, responsible for clients in northern Poland, points out the increasing level of sophistication of applications being implemented in Polish factories. According to him, the Smart Automation project for Bruss Polska is a perfect example of this trend.

The line consists of several cells, including two robotic cells that use KR AGILUS series robots,” says Łukasz. “Robots from this series are characterized by excellent accuracy and repeatability, while occupying relatively little space. This makes them ideal for applications where space is limited.

Are you interested in our offer?

Leave your contact and tell us what we can do to help - we'll get back to you.