Production automation in the furniture industry

Smart Automation automated the assembly process of furniture fittings at its client’s facility, a leading furniture manufacturer, ensuring high efficiency, repeatability, and production stability.

Challenges

The project presented a unique challenge due to the variety of the product range, complex assembly processes, and the high level of automation required for proper machine operation. Smart Automation successfully designed and implemented an initial version of the assembly line. The initial deployment revealed several difficulties, such as system instability, high complexity, and limited access to critical service and maintenance points. As a result, the company decided to completely redesign the assembly line, optimizing the use of already manufactured components. This approach significantly reduced project costs and minimized the overall footprint of the workstation.

At first glance, the project for an automatic fittings assembly machine seemed straightforward, but during its implementation we encountered numerous challenges. This is an example of highly specialized equipment that clients cannot find on the market. We therefore developed several prototypes, which allowed us to test different concepts and identify and eliminate specific risks,’ explains Radosław Kokornacki, Head of the Automation Department at Smart Automation.

„Then came the pandemic period, which significantly impacted supply chains. The client received semi-finished products made from alternative materials, which forced us to adopt a new strategy and update our production processes. Implementing innovative solutions became essential to adapt the equipment to the changing conditions. This external factor—the changes in component materials—affected the project schedule. We had to conduct detailed verifications and a series of tests to ensure that the implemented modifications met all the requirements set by our client, which we successfully achieved,” says Sebastian Skibowski, Lead Designer at Smart Automation.

Solutions

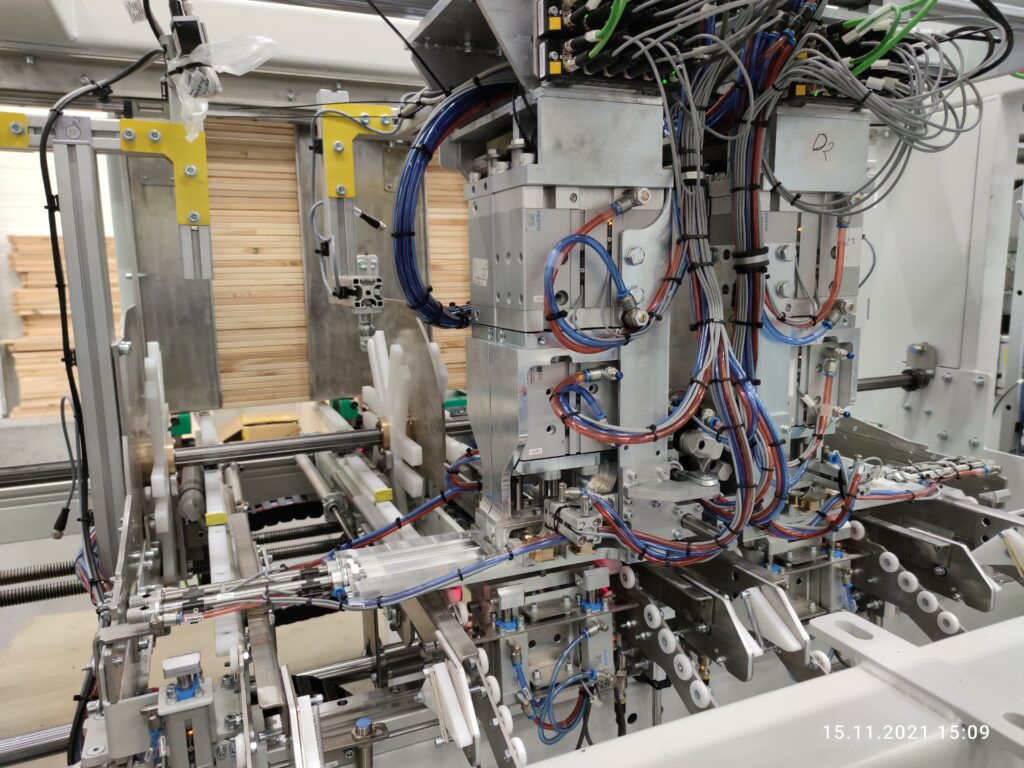

In the case of automating the assembly process of furniture fittings, a key challenge was the proper adjustment of production equipment settings. The solution implemented by Smart Automation had to account for the varying strength of materials used in the facility, their specific characteristics (e.g., knots), dimensional variability of the manufactured products, and the cycle and method of component positioning. Due to the sensitivity of the materials to damage, it was necessary to develop specialized assembly techniques to minimize risk. Ensuring top-quality equipment to guarantee the final product quality was also crucial.

„These criteria were achieved, among other things, thanks to the Siemens solutions implemented in the project. We decided to use a control system based on the S7-1500 Software Controller PLC with integrated safety functions,’ explains Radosław Kokornacki, Head of the Automation Department at Smart Automation.

Siemens solutions were applied in the project.

Technologies Used

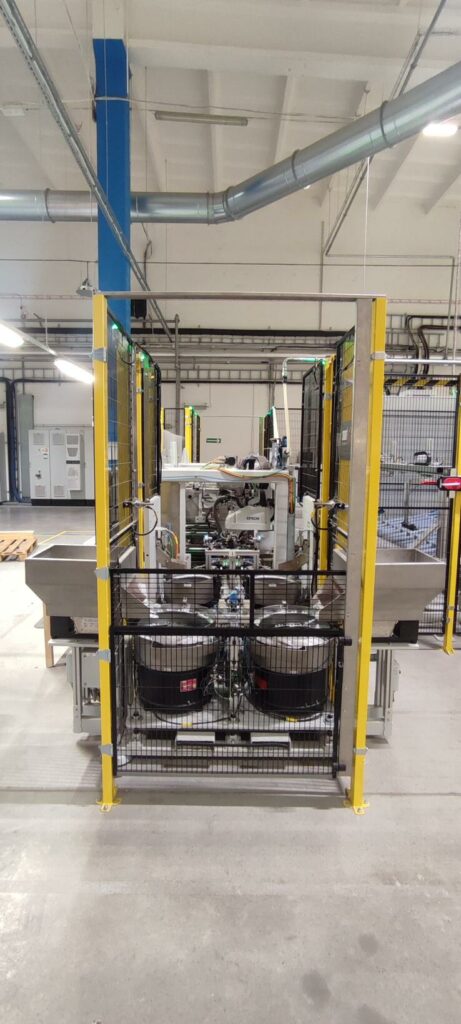

The fittings assembly machine was designed by Smart Automation to allow integration with existing production systems. Workplace safety requirements were also taken into account. In the areas of measurement and vision systems, drives, and process visualization (HMI screen), Siemens solutions were implemented.

Some components of the solution – fixtures for positioning the locking pins of the fittings – were manufactured using Selective Laser Sintering (SLS), a 3D printing method. The pins required precise positioning within the fittings, and their specific shape necessitated the creation of multiple fixture prototypes,’ explains Sebastian Skibowski, Designer at Smart Automation.

Due to the short production cycle, the project required the use of high-performance components. This requirement led to the necessity of incorporating a Siemens SINAMICS servo drive in the pin-feeding module, characterized by compact dimensions, high precision, and dynamic performance. Thanks to the use of the servo motor, the loading time for the pin packs needed for assembly was reduced to under 2 seconds.

A key element of the Smart Automation production automation solution is the control system. The project employed an Open Controller — a PC-based controller housed in an enclosure typical for the ET200SP I/O system — serving as the main controller. Its short command execution cycle, combined with large memory capacity, allows processing and temporary archiving of significant amounts of data. Additionally, the Open Controller enables the implementation of an archiving system.

The controller provides sufficient computing power to allow future expansion of the line with additional loading and unloading modules. The achievement of the required cycle times was also supported by a user-friendly programming environment.

,,The integrated TIA Portal development environment allowed us to prepare the visualization, control program, safety program, and configure the drives without the need to switch between different software components,’ emphasizes Radosław Kokornacki from Smart Automation. During implementation, all programming tasks were completed using a single software package.

‘By utilizing the TIA Portal program library, we were able to standardize and version software objects, including across different projects. This approach significantly accelerates programming time by leveraging standardized solutions used in previous projects,’ adds the Head of the Automation Department at Smart Automation.”

Automation Results and Implementation Benefits

Before automation, eight workstations operated by eight employees installed between 3,000 and 3,500 fittings. The operator manually positioned the fitting components on the board and then inserted the pin. Subsequently, both elements were pressed together using a pneumatic press.

Currently, thanks to process automation, the operator is only responsible for selecting the recipe and replenishing the boards and bins with fittings and pins. The machine independently assembles all components, producing a finished product ready for packaging and shipment to the client.

A key benefit of production automation is achieving consistent, high-quality components manufactured in a repeatable manner. The vision system evaluates the quality of the final product and notifies the operator of any defects.

Production speed has also increased. The machine designed and implemented by Smart Automation operates with a cycle time of 4–5 seconds. As a result, the device can produce up to 6,500 units within an 8-hour workday. This is made possible by process optimization and the parallel execution of several operations, significantly reducing the production time for a single component. Thanks to production automation, more orders can be processed, leading to higher plant efficiency and increased revenue.

An important feature of the implemented solution is the possibility of further increasing production capacity and product range. The machine was designed so that, in the future, new components within a specified dimensional range can be added and assembled without modifying the equipment. Introducing a new final product to be manufactured by the machine involves creating and implementing a new recipe.

“Automating repetitive processes brings a range of benefits to industrial companies — increased efficiency and faster production, lower costs, and the ability to reassign employees to more demanding tasks are just a few examples — explains Sławomir Kalita, Sales Manager at Siemens Poland. — In this implementation, Smart Automation utilized a number of Siemens solutions. Their selection was not accidental. Using complementary hardware devices and tightly integrated software from a single manufacturer significantly streamlines the work of the technical department while increasing confidence in the final results. In this case, an innovative machine was created that, on one hand, showcases the expertise of Smart Automation specialists, and on the other, demonstrates the wide applicability of Siemens components in customized industrial solutions” — adds Sławomir Kalita.

Are you interested in our offer?

Leave your contact and tell us what we can do to help - we'll get back to you.