Facing rising media costs, the need to optimize energy efficiency, and meet sustainability goals, manufacturing companies encounter significant challenges. SMART+ Media Monitoring is an innovative tool that not only addresses these issues but also enhances the competitiveness of production facilities.

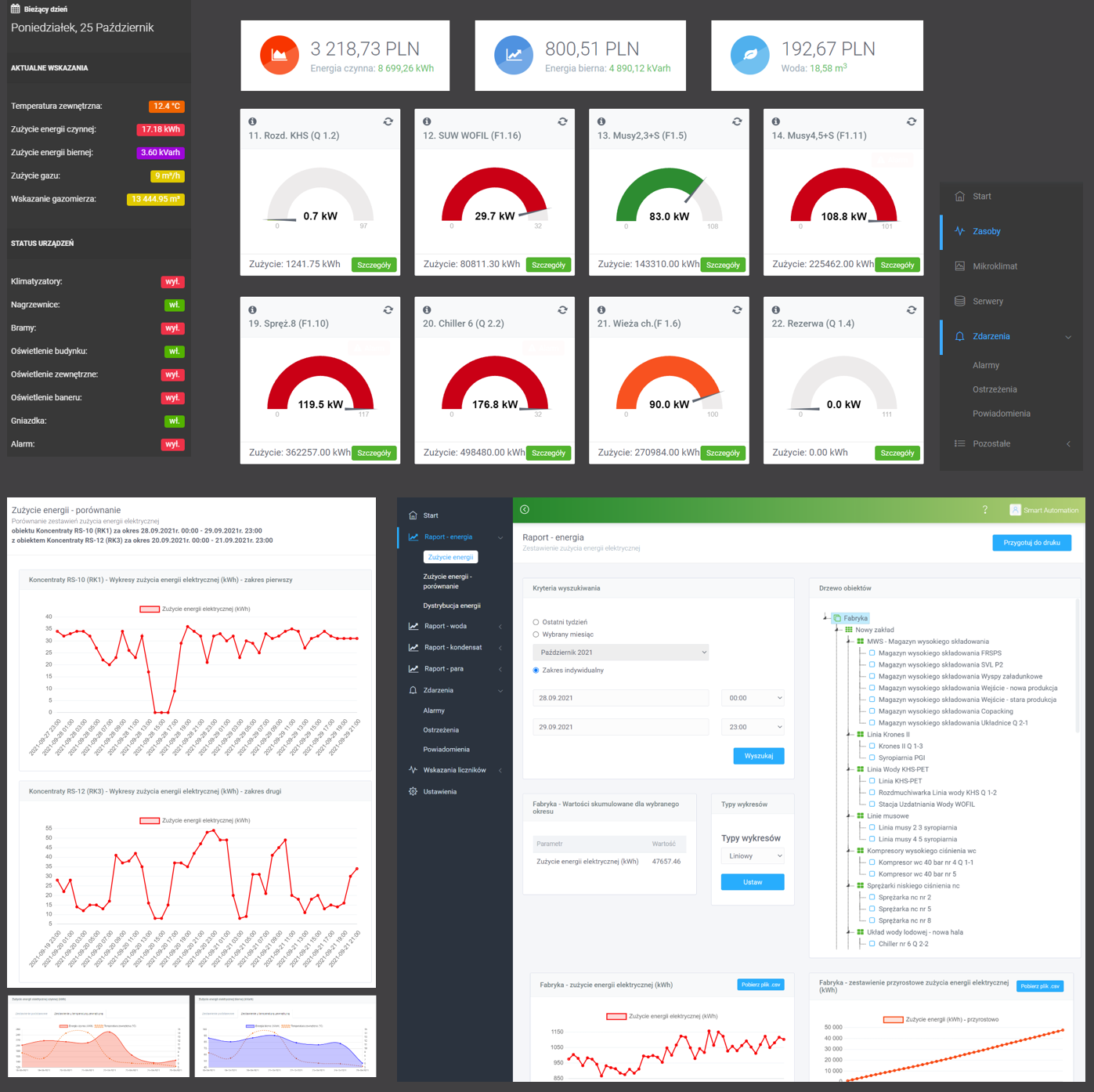

Our system provides full control over media consumption, enabling real-time analysis, automatic reporting, and precise production cost summaries.

Challenges in media management and their solution

Challenges in the Manufacturing Industry:

- Rising media costs: Increasing energy and water prices are a significant issue for many companies.

- Energy efficiency optimization: Many facilities struggle with the lack of precise data needed to make informed decisions.

- Sustainable development: Reducing the carbon footprint and minimizing media losses are key objectives for many companies.

How SMART+ Addresses These Challenges:

- Accurate consumption data: Monitoring key media in real time.

- Cost optimization: Enabling loss reduction and improved operational efficiency.

- Simplified billing: Automatic reports allocating costs to facilities, products, and employees.

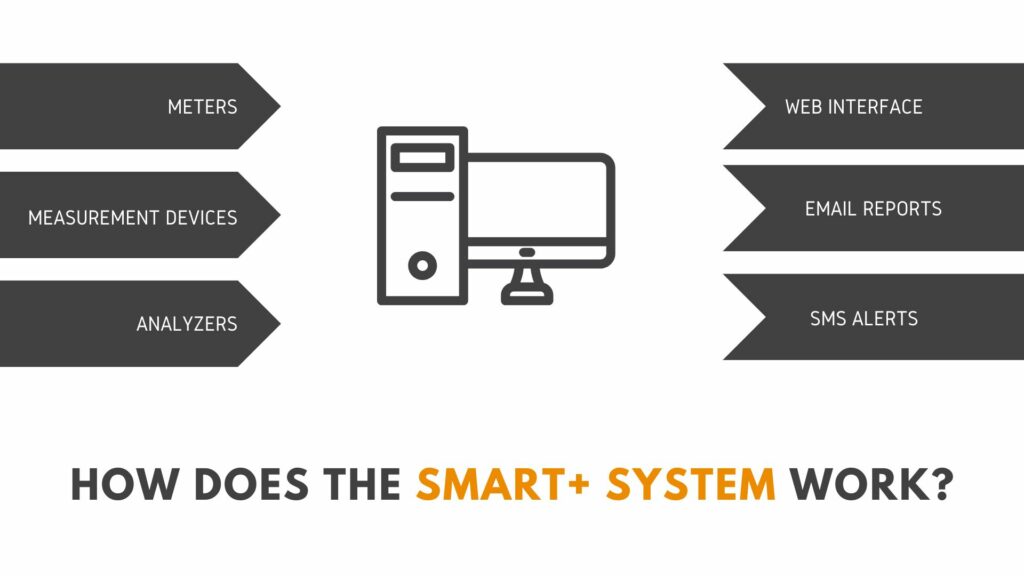

How does the SMART+ System work?

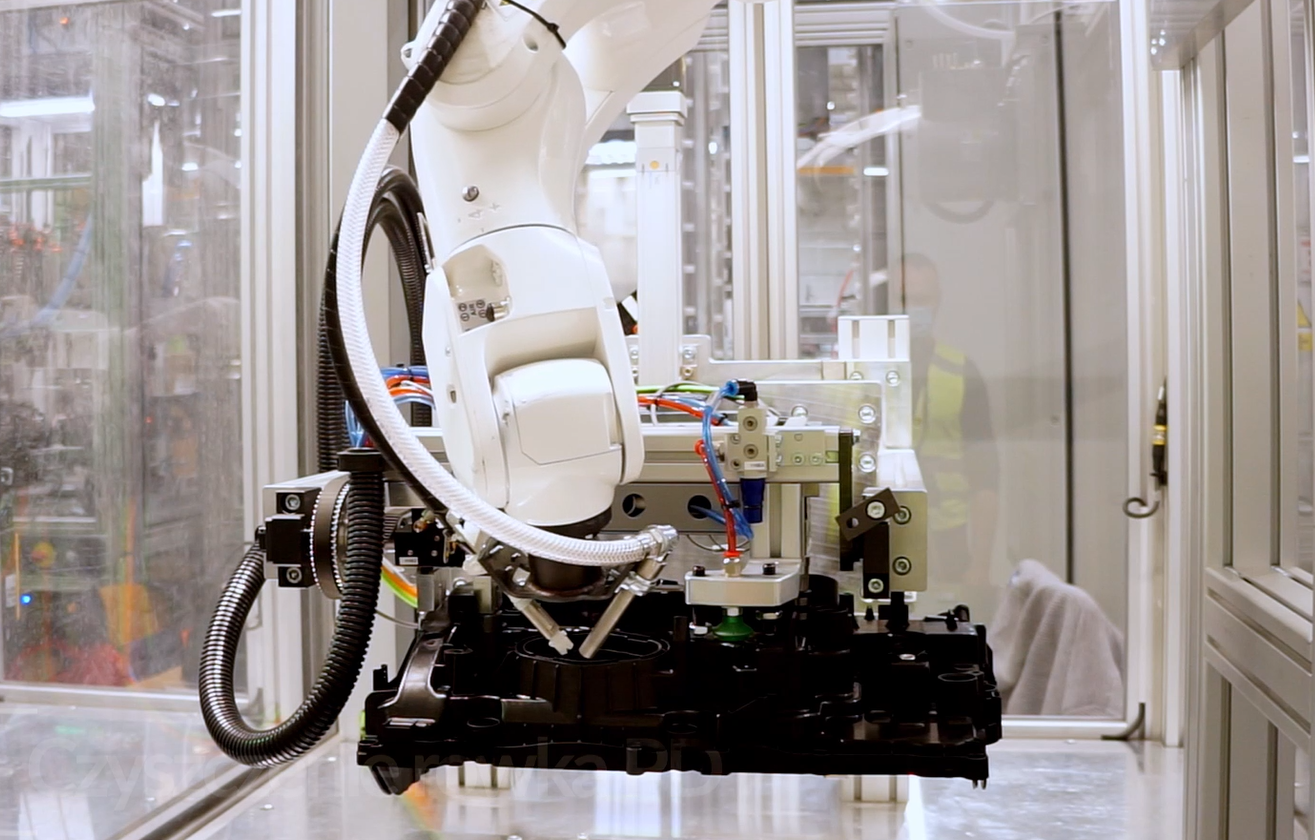

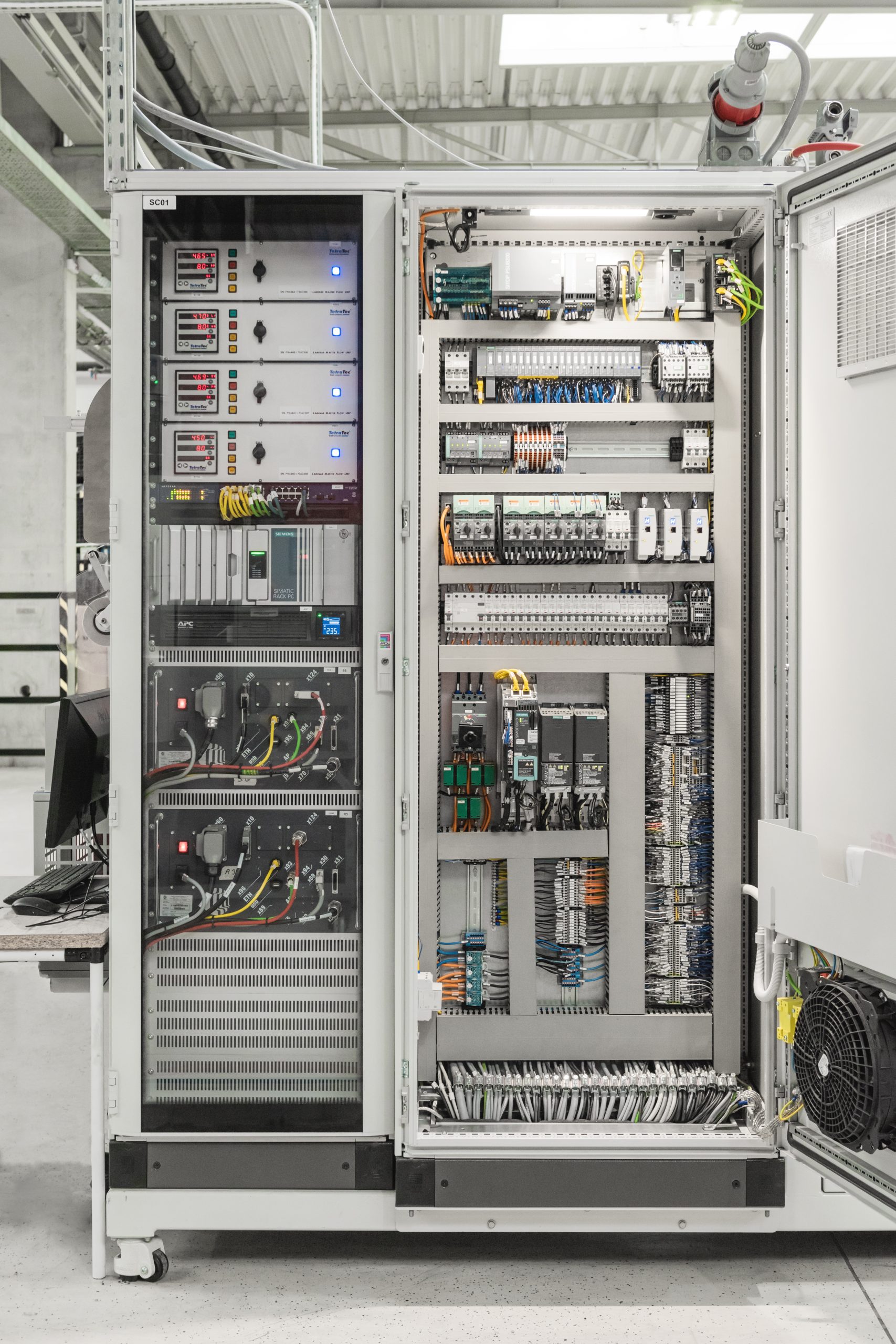

Complete Infrastructure: Meters, analyzers, sensors → SMART+ System → Access via browser, email reports, SMS alerts.

System Operation Steps:

- Data Centralization:

- Data from meters and measurement devices are collected in a single location, providing full insight into media consumption within the facility.

- The system supports various types of media, such as water, energy, steam, and other raw materials.

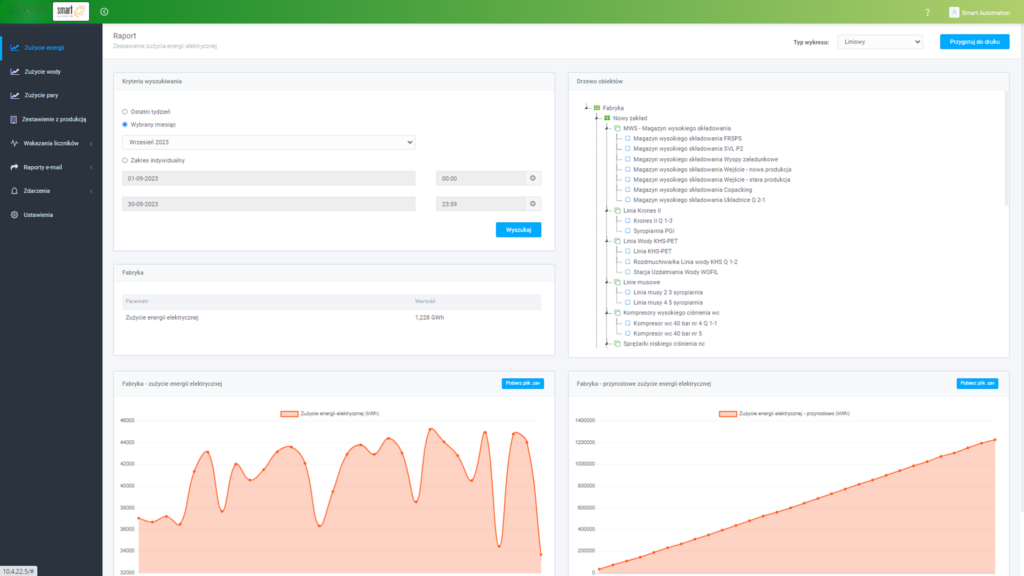

- Real-Time Analysis:

- Data is processed and analyzed continuously, enabling rapid detection of anomalies and real-time decision-making.

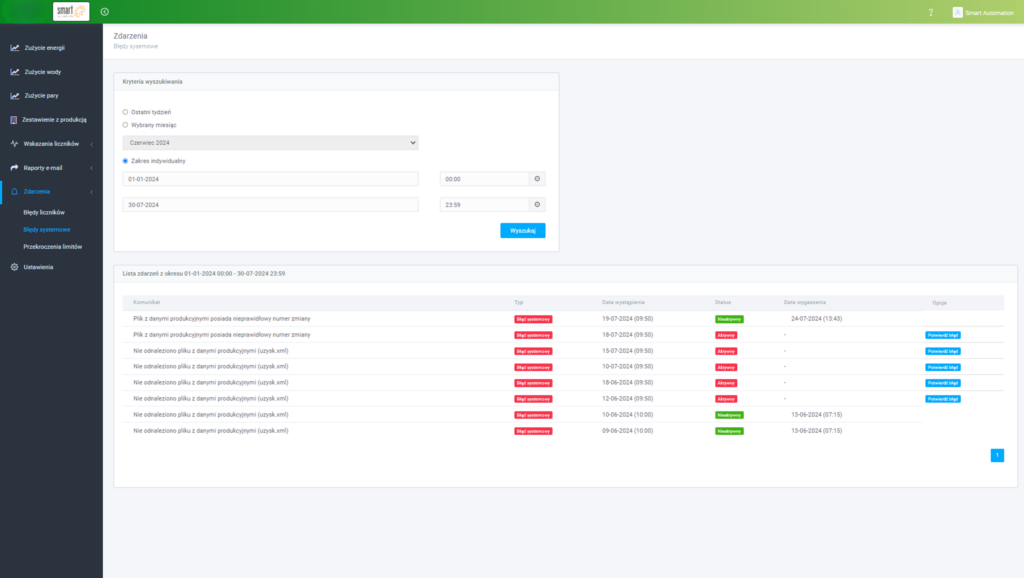

- Automatic Reporting:

- Technical Reports: Detailed data on system errors and monitoring.

- Production Reports: Calculations of media consumption per unit of product produced.

- Event Reports: Alerts on exceedances, allowing immediate response.

Key features and benefits of SMART+

Key Features of the System:

- Notification mechanism (SMS/email) for anomalies and failures.

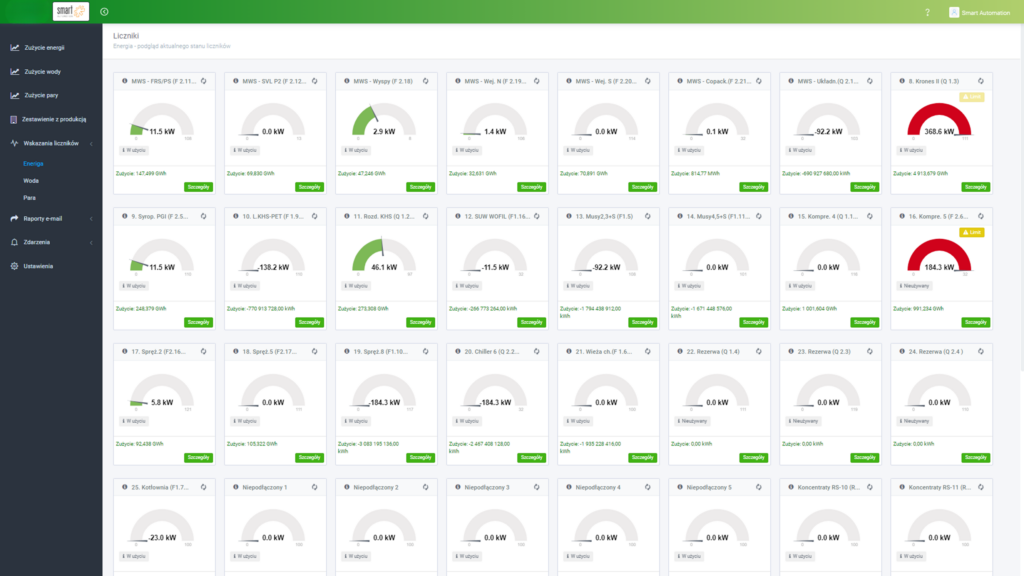

- Platform for remote real-time media monitoring.

- Automatic generation of daily, weekly, and monthly reports.

- Optimization of tariffs and contract power, helping to reduce energy costs.

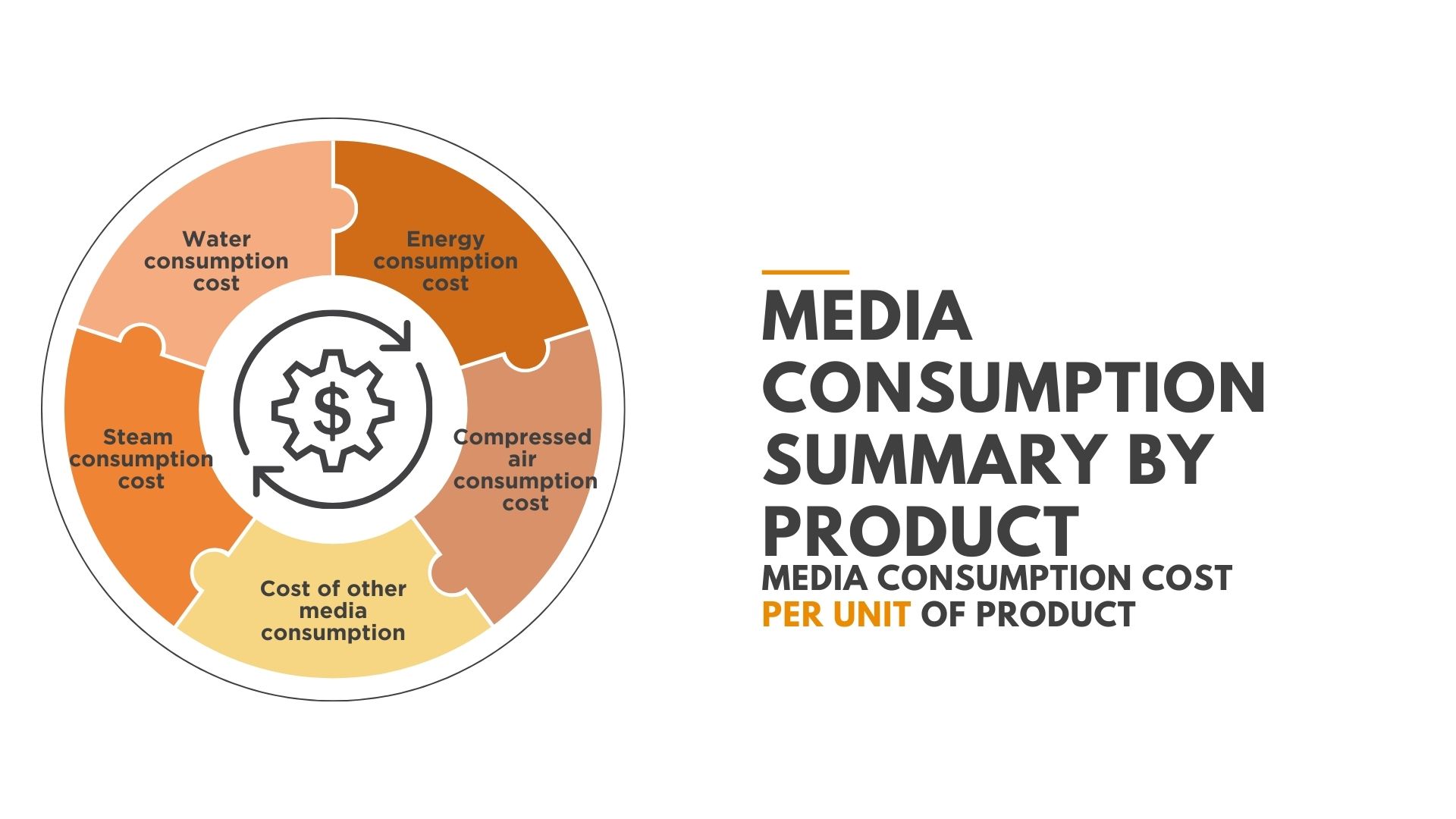

- Media consumption per unit of product, enabling precise cost calculations.

Benefits for the Client:

- Immediate control: Ability to respond quickly to events and detect losses.

- Accurate billing: Data assigned to specific facilities, products, and activities.

- Efficiency improvement: Reduction of production losses, such as air leaks or inefficient machine changeovers.

- Support for sustainable development: Reduction of media consumption and carbon footprint.

Use Case 1: reporting exceedance of declared power

Problem: The client was incurring financial penalties for exceeding power above 30,000 W.

Solution: The SMART+ system reacts immediately to declared power exceedances by sending notifications to key personnel.

Process Flow:

- The main meter records the power exceedance.

- The system detects the event and generates an alarm.

- Shift managers receive an SMS with instructions to reduce consumption.

- Management receives an email with a full event report.

Benefits:

- Elimination of financial penalties.

- Rapid response to critical events.

- Improved energy efficiency.

Use Case 2: monitoring energy consumption by facilities

Problem: The client was unable to monitor energy consumption on the production line without a separate meter.

Solution: SMART+ calculates energy consumption by differentiating readings from main and auxiliary meters.

Process Flow:

- Creating an object in the system (“Capacitor Production Line”).

- Calculating energy consumption as the difference between meters.

- Data is recorded every 15 minutes.

- Reports can be generated via the browser.

Benefits:

- Full control of energy consumption on selected production lines.

- Ability to analyze and optimize processes.

Use Case 3: Correlating media consumption with production volume

Problem: The client required a report correlating media consumption with the production of different product variants.

Solution: The SMART+ system automatically generates reports by integrating data from ERP and media monitoring.

Process Flow:

- ERP provides data on the number of products produced.

- The system monitors media consumption on production lines.

- The report combines production and media consumption data.

- The report is sent via email to responsible personnel.

Benefits:

- Automation of daily reporting.

- Accurate data for analyzing production efficiency.

- Ability to optimize processes based on precise information.

Why Choose SMART+?

- Full media control: Real-time data.

- Accurate billing: Automatic reports and summaries.

- Flexibility: Ability to adapt to the specifics of each facility.

- Sustainable development: Optimization of resource usage and reduction of losses.

Quote from the SMART AUTOMATION Team

Our SMART+ system is custom-designed for each facility, making full use of the existing measurement infrastructure. Thanks to the system’s nearly unlimited expandability, we offer solutions perfectly tailored to our clients’ needs — both visually and functionally.

Are you interested in our offer?

Leave your contact and tell us what we can do to help - we'll get back to you.